Understanding Injection Robots

What is an Injection Robot?

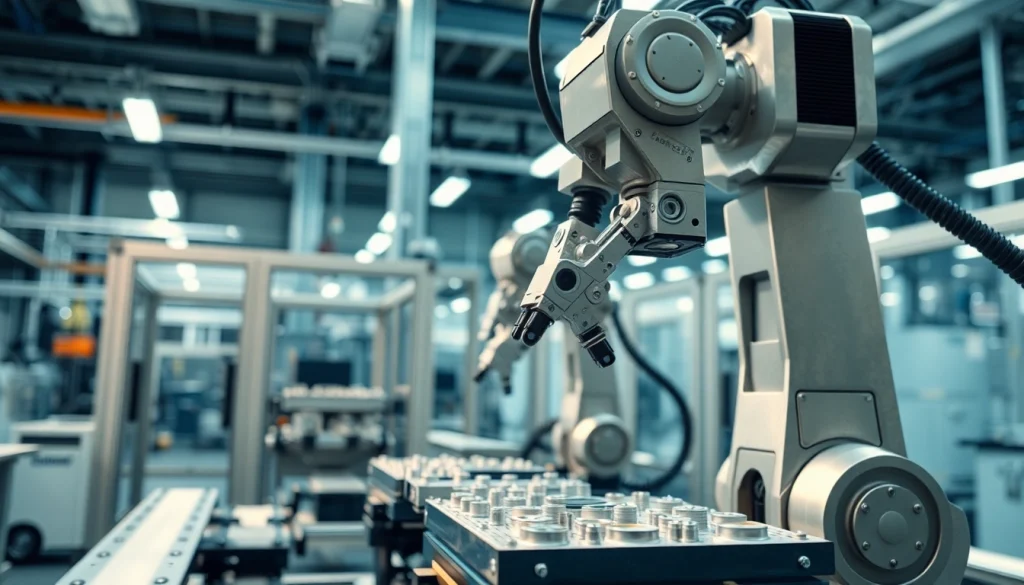

Injection robots are automated systems designed to enhance the injection molding process, particularly in the manufacturing industry. They integrate robotic arms with advanced technology to facilitate the precise placing, handling, and assembly of products during the injection molding cycle. By automating processes that were previously labor-intensive, these robots not only improve productivity but also increase the quality of output. In essence, an Injection Robot efficiently combines speed, precision, and repeatability to meet the growing demands of modern manufacturing.

Key Features of Injection Robots

Injection robots come equipped with several key features that distinguish them from other types of automation equipment:

- High Precision and Repeatability: Injection robots utilize precision servo motors, ensuring that each operation is completed with exact accuracy. This leads to fewer defects and reworks.

- Speed: The advanced mechanics of injection robots allow for rapid movements that shorten cycle times significantly, thus accelerating production rates.

- Flexibility: Many injection robots are programmable, allowing manufacturers to adapt these robots for various tasks or products without significant reconfiguration.

- Connectivity: Modern injection robots often feature IoT integrations that facilitate real-time monitoring and adjustments, optimizing the manufacturing process.

Types of Injection Robots Available

There are several types of injection robots, each serving different needs within the industry:

- Articulated Robots: These robotic arms feature rotary joints and are known for their versatility and range of motion.

- Cartesian Robots: Also known as linear robots, these machines operate on three linear axes and are highly accurate, making them ideal for various assembly tasks.

- Delta Robots: Characterized by a parallel arms design, delta robots excel in picking, packing, and assembly applications due to their high speed and flexibility.

Advantages of Using Injection Robots

Increased Precision and Speed

One of the primary benefits of injecting robots is the increased precision and speed they bring to manufacturing. Automation allows for fewer human errors and greater consistency in molding processes. High-speed robotic arms can complete tasks in a fraction of the time it would take a human, allowing companies to significantly increase output without compromising quality.

Cost-Effectiveness and ROI

Injection robots minimize labor costs and reduce scrap rates, making them a cost-effective solution over time. Although the initial investment might be substantial, the return on investment (ROI) can be realized through increased production efficiency, lower labor costs, and enhanced quality. Furthermore, the ability to produce more units in less time allows companies to broaden their market reach and improve profitability.

Consistency in Production Quality

The introduction of injection robots ensures that every piece produced meets the same high standards. Consistency in production quality is critical, particularly in industries like automotive or pharmaceuticals, where deviations can lead to significant setbacks. The precision provided by robotic systems helps manufacturers uphold stringent quality control measures, reducing the chances of defective products reaching the market.

Implementing Injection Robots in Your Facility

Assessing Your Operational Needs

Before implementing an injection robot, it is crucial to assess your operational needs thoroughly. Identify processes that require improvement, check for bottlenecks, and evaluate your product types. Conducting a comprehensive needs assessment will enable you to choose the right robotic system and tailor it to your facility’s specific demands.

Integration with Existing Systems

Integrating an injection robot into your existing manufacturing setup can be daunting. It requires careful planning to ensure compatibility with current machinery and workflows. The integration phase may involve upgrading software, modifying existing equipment, or investing in new technology. A phased approach often yields the best results, allowing for adjustments and optimizations during implementation.

Training Your Workforce for Success

Even with automation, the workforce remains a critical component in manufacturing. Training employees to work alongside injection robots ensures smooth operation and minimizes disruptions. Focus on providing hands-on training, highlighting safety protocols, and emphasizing the importance of monitoring robotic performance to maintain quality standards.

Common Challenges in Using Injection Robots

Addressing Initial Setup Costs

One of the common challenges manufacturers face is the initial investment required for setup and integration of injection robots. While financing options are available, companies must be prepared for the upfront costs. A thorough cost-benefit analysis can help illustrate potential savings over time and justify the investment to stakeholders.

Maintenance and Upkeep Considerations

Regular maintenance is critical to keeping injection robots in optimal working order. Scheduling preventative maintenance checks and addressing minor issues before they escalate can save time and money in the long run. Organizations should develop a maintenance schedule and perhaps consider service contracts with providers to ensure consistent upkeep.

Handling Technical Issues Effectively

Technical complications can arise with any automated system, and injection robots are no exception. Having a clearly defined troubleshooting protocol can streamline the response to technology-related issues. Additionally, training staff to understand common problems and solutions can mitigate downtime and keep production on track.

Future Trends in Injection Robotics

Advancements in AI and Automation

The future of injection robotics is closely tied to advancements in artificial intelligence (AI) and machine learning. Integrating AI capabilities allows robots to learn from previous operations, enhancing their efficiency and performance. This evolution will lead to increased autonomy, providing manufacturers with the ability to optimize operations dynamically.

Scalability and Customization Options

As businesses grow and adapt, the need for scalable and customizable robotic solutions becomes more evident. Injection robots are increasingly being designed to serve a broader range of applications and can be easily modified to accommodate changing production needs. This flexibility ensures that manufacturers can remain competitive in a rapidly evolving market.

Impact on the Future of Manufacturing

The adoption of injection robots will play a critical role in the future of manufacturing. As technology continues to advance, companies that integrate robotic systems will likely experience greater efficiencies, reduced costs, and improved product quality. The shift toward automation will also redefine job roles within manufacturing, emphasizing the importance of technical skills and adaptability among the workforce.